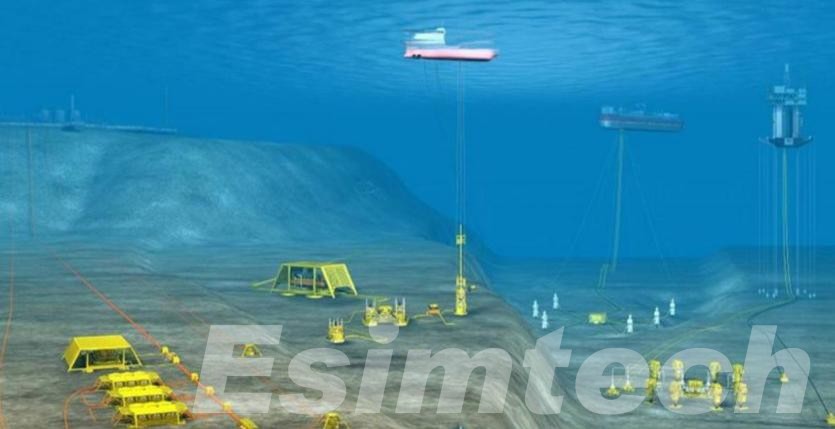

Offshore exploration is racing outward and downward, stitching a web of deep-water projects that demand ever more robust subsea production systems. Although today’s hardware—wellheads, manifolds,

multiphase pumps and electro-hydraulic umbilicals—has logged decades of run time in the North Sea, Gulf of

Mexico and Brazil, operators still face a trio of technical hurdles: seabed processing, equipment durability and flow assurance. Tackling these challenges is essential to unlock remote reservoirs and to help newcomer provinces, most notably China, chart a path toward technology independence.

1 · Seabed Processing: From Vision to Reality

The ultimate goal of next-generation subsea systems is “sea-bottom factories” that separate, boost, and even re-inject produced fluids without a crewed platform overhead. Placing separators,

scrubbers, and multiphase pumps on the seabed slashes back-pressure, raises recovery factors by several percentage points, and trims the carbon footprint linked to topside utilities. Early prototypes in Norway’s

Åsgard field and Brazil’s pre-salt have proved technical viability, but widespread adoption hinges on cheaper,

lighter and easier-to-maintain modules capable of surviving 25–30 years in 3,000 m water depth.

2 · Equipment Reliability Under Extreme Conditions

Deep-sea wellheads, valves and control pods must endure hydrostatic pressures above 30 MPa, corrosive brines, and ambient temperatures close to 0 °C. Materials science is therefore at the core of reliability engineering—from duplex stainless and Inconel alloys to non-metallic seals formulated for wide temperature swings. Equally critical is the evolution of control philosophy: the industry has progressed from direct-hydraulic actuation to hybrid electro-hydraulic lines, and is now experimenting with all-electric actuation to eliminate hydraulics altogether. Each leap promises faster response, simpler umbilicals and fewer leak paths—yet also demands rigorous testing to prove long-term integrity.

- Pressure & Corrosion Resistance . Qualification of new steels and cladding techniques.

- Redundant Control Logic. Dual or triple hot-swappable electronics pods.

Sensors & Diagnostics. Fibre-optic strain gauges and acoustic leak detection feed digital twins that predict failures before they disrupt production.

3 · Flow Assurance in Submarine Pipelines

Wax, hydrates, sand, and severe slugging can choke production or fracture pipelines. Ensuring steady flow

across a field’s life demands a toolbox of thermal insulation, chemical injection and smart pigging

strategies:

- Hydrate Mitigation. Low-dose inhibitors and active heating keep fluids above hydrate-forming temperatures during shutdowns.

- Wax & Sand Control. Paraffin dispersants, internal coatings and sand screens reduce deposition and erosion.

- Slug-Flow Management. Transient-flow simulators shape pipeline profiles and riser base gas-lift to smooth out liquids surges.

- Corrosion Monitoring. Real-time pH and CO2 probes feed corrosion-rate models guiding pigging and inhibitor dosage.

4 · Emerging Technologies on the Horizon

Researchers are pushing boundaries in five cutting-edge domains:

- Long-Distance Tie-Backs . All-electric boosting plus subsea compression aims to extend flowlines beyond 200 km.

- Deep-Sea Power Distribution. High-voltage wet-mate connectors and seabed switchgear promise plug-and-play flexibility.

- Autonomous Installation. Resident ROVs and AUVs speed up module swap-outs and visual inspections without daily vessel costs.

- Integrity Management. Integrated data lakes and machine learning convert vibration, pressure and acoustic signatures into asset-health dashboards.

- Polar-Ready Hardware. Specialised insulation and antifreeze hydraulics prepare equipment for Arctic prospects.

5 · China’s Deep-Water Roadmap

China’s offshore portfolio is shifting from Bohai’s shallow waters toward the East and South China Seas.

Success hinges on mastering four imperatives:

- Technology Transfer & Localization. Partnering on early projects while building indigenous manufacturing capacity for trees, manifolds and umbilicals.

- Pilot Projects. Deploying demonstrator fields to gain operational data under real deep-water conditions.

- University–Industry Collaboration. Funding joint R&D in materials science, digital twins and flow assurance.

- Regulatory & Safety Frameworks. Establishing standards that incentivise innovation without compromising environmental stewardship.

The march into deeper waters is inevitable—and with it, the reliance on sophisticated subsea production systems. By innovating in seabed processing, ruggedized equipment and bullet-proof flow assurance, the global industry can unlock stranded reserves while trimming costs and emissions. For China and other emerging deep-water nations, coupling foreign experience with aggressive local R&D will be key to breaking technology dependencies and securing a sustainable offshore future.

© 2025 Prepared for educational reference. | Learn more at ESIMTECH’s knowledge base.